|

|

Non Woven Auto Bag Making Machines |

|

|

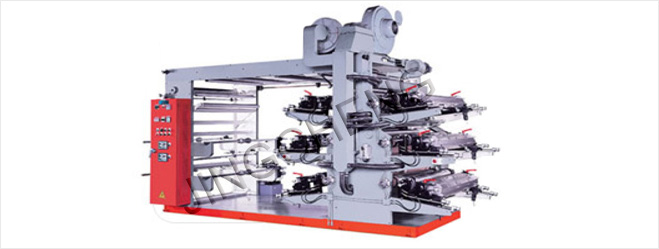

FM 61200 Non-woven flexographic printing machine series |

|

| |

| Technical Parameter: |

|

| 1 |

Ink |

| |

Adopt the automatic circle system ,running ink by single small motor ,with the electrical clutch device |

| 2 |

Timing |

| |

Adopt Japanese inverter controlled , running by small fluctutations. |

| 3 |

Unwinder EPC |

| |

Adopt the high quality automatic EPC controller device |

| 4 |

Unwinder and rewinder way |

| |

Adopt the magnetism Auto tension controller |

| 5 |

Ink way |

| |

Our company has special design for the doctor blade device with the ink pump can suck the ink automatically. |

| 6 |

Up and Down plate |

| |

Adopt the hydraulic pressure for up and down movement of printing plate automatically. |

| 7 |

Roller |

| |

Adopt special steel processing and through special technique of treatment, and plate thickness of 10 silk

protective layer of hard chromium ,beat the following in the 0.02mm |

| 8 |

Traction Rollers |

| |

Adopt japanese production of semi-enclosed bearing, static equilibrium & dynamic levels of cross processing

hard oxidisation,treatment , resistance, beating a small. |

| 9 |

Drying Device |

| |

Ventilation with heat blowing three devices , which use a central heating, temperature control system and the

control each group |

|

|

|

|

| |

| Main Parameter: |

|

| Model |

FM61200 |

| Max Width of Material |

1200mm |

| Max.Width of Printing |

1160mm |

| Material |

| Non-woven fabric |

15-120g |

| Paper |

15~400g/m2 |

| Aluminium foil |

30~150μm |

| Woven Fabric Material |

15-500g/m2 |

| PVC |

15~120μm |

| BOPP |

10~100μm |

| PE |

15~150μm |

| NY |

15~120μm |

| PET |

15~100μm |

| CPP |

15~100μm |

|

| Printing color |

6 color |

| Max.Length of Printing |

200-1100mm |

| Machinery mechanical speed |

10-90m/min |

| Max.Speed of Material Printing |

10-70m/min |

| Thickness of Plate including glue |

2.38mm |

| machine weight |

5100kg |

| machine dimension (L×W×H) |

5m×2.2m×3.05m |

| Power |

Voltage:380V,3PH,50HZ |

| Unwind Unit |

| Max.Length of Roller |

1000mm |

| Max.Width of Printing |

1200mm |

| Max.Dia. of Unwind |

¢1000mm |

| Type of Unwind |

hydraulic type of wind and unwind |

| Unwinder Magnetism device |

5kg |

| Auto Tension Controller Unwinder |

2—20kg |

| Unwinder EPC |

Electrical Edge Correction Device |

| Feeding shaft |

Air shaft |

| Axis core diameter¢ |

76mm |

| Traction Unit |

| Constitution of Traction |

Aluminum roller, chrome plated roller |

| Traction Zones |

6 Zones |

| Printing Unit |

| Constitution of Printing |

Anilox roller, Rubber roller, Chrome Plated roller |

| Girth of pressing roller |

200-1050mm |

| Material of Plate |

Resin or Rubber |

| Principle of Work |

Gears Drive |

| Adjusting of Registe |

Manual |

| Overprint Precision(mm) |

Horizontal:+-0.2mm、Vertical:+-0.15mm |

| Plated-glued roller adjusting |

hydraulic type of plate-cylinder |

| Anilox Roller |

Titanium Anilox Roller (made in Germany) |

| Rubber rollers |

1 pcs/per color |

| Heating and Drying Unit |

| Type of Heating and drying |

blowing first then heating |

| Heating Zones |

11 zones |

| Power of Heating |

11kw |

| Assistance of Drying Length |

1.5m |

| Blowers |

3 Fans |

| Power of Blowers |

1.5kw*2pcs |

| Electrical Parts |

| Main motor |

3.7kw |

| Ink-Transfer Motor |

0.2kw |

| The inverter |

3.7kw |

| Tension test |

2--30kg |

| Wind Unit |

| Max Width of Material |

1200mm |

| Max.Dia of Wind |

¢1000mm |

| Rewinder Magnetism Powder |

5kg |

| Auto tension controller |

2—30kg |

| Axis core diameter |

¢76mm |

|

|

|

|

| |

| Main Machine Specification List |

|

| Main Motor |

1 pcs 3.7kw (Taiwan) |

| Ink transfer motor |

1 pcs 0.2kw (Taiwan) |

| The transducer |

(Panasonic Japan) |

| Blower |

2 pcs 1.5kw (Fengyang Shanghai) |

| Aluminum Rollers |

BaiXiao RuiAn |

| Anilox Roller |

1 pcs/per color Titanium Anilox Roller (made in Germany) |

| Auto tension |

1set (ShangHai Tension Equipment co.,LTD) |

| Air shaft |

1set (RuiAn QiangGuang) |

| Magnetic powder |

1set (Ruian zhongrui co.,LTD) |

| Rubber rollers |

1 pcs/per color (own products) |

| Low pressure Electricals |

Siemens |

| Normal bearing |

NSK from Japan |

| Unilateral bearing |

ASNU from German |

| Switches |

Schneider emluator |

| Electrical control Box |

1 set (own products) |

| Main machine body |

1 set (own products) |

|

|

|

|

| |

| Spare Parts For Free |

|

| S.NO. |

Name of the spare parts |

Quantity |

| 1 |

Tool Box |

1 set |

| 2 |

1-10# screwdriver |

1 pcs |

| 3 |

Oil gun |

1 pcs |

| 4 |

Inner Hexagon Spanner |

1 set |

| 5 |

Switches |

2 pcs |

| 6 |

Contactor |

2 pcs |

| 7 |

Heating tube |

2 pcs |

| 8 |

Machine operation instruction |

1 pcs |

| 9 |

The inverter instruction |

1 pcs |

|

|

|

|

| |

| |

|

|

|