|

|

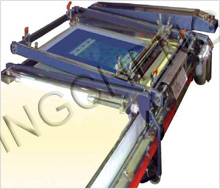

Screen Printing & Dyeing Equipment |

|

|

Flat Screen Printing Tables |

|

| Printing Carriage |

Rubber Squeegee System :

Comprising of a Galvanized robust Steel fabricated Framework, supported on a series of Locating Carrier Wheels, and retaining the following:

| • |

A hinged Screen Holding Frame, suitably prepared with adapters for the Asian and European Type Flat Screen Setting/Locking systems, |

| • |

Pneumatic operated Screen Lifting mechanism, |

| • |

A Motorized Variable Speed Squeegee Drive system, complete with adjustable Travel Limiters, PLC Controlled for Multi-Stroke and Flood-Stoke Colour Application. |

|

|

|

| • |

Sprung loaded Squeegee Retainers complete with calibrated settings for controlling the Colour Application by the Squeegee system. |

| • |

A Motorized Variable Speed Print Carriage Drive system, PLC Controlled for Auto-engaging of the Print Carriage to the Repeat Settings, complete with related Electronic system for controlling the Print Carriage Auto / Alternate / Manual Travel Mode. |

| • |

A Fabric Roll Support/Spreading attachment, useful for the Operator to apply the Fabric onto Print Table Surface |

|

| |

The Electrical and Pneumatic Control Cabinet suitably connected to Printing Head Frame unit, housing all related Operational Switch-gear, together with Operator Control panel, all ready prepared for incoming Supply. |

| |

PRINTING TABLE

Comprising of a Galvanized Steel Base-frame Structure, retaining a Reinforced Marine Plywood Table Surface, and covered with 2 layers of Polyester Under-Felt (for ~Soft~ Print Table System) and a Polyester/PVC coated Print Blanket, inclusive of necessary Print Carriage Runner Rails, a series of adjustable Repeat Blocks for Auto-engaging of the Print Carriage to the required Repeat settings, and Drainage side Channels.

The Printing Table being equipped with a 3 Phase Electrical Supply Conductor Rail System, and a Retractable ~Drum~ Type Pneumatic Air Supply System for Operational Services to the Print Carriage and other related Optional Extra Accessories.

TABLE HEATING SYSTEM

An Electrical Heated Under-blanket System is offered as Optional Extra, for maintaining the Print Table Surface heated up to 65 Deg Cent., comprising of a special Wire Mesh for enclosing between the 2 Layers of Under-felt, complete with Auto-Transformer for Setting the desired Temperature. |

| |

|