|

|

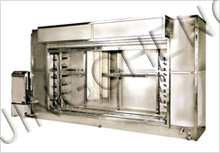

Screen Printing & Dyeing Equipment |

|

|

Rotary Colour Pipes Washing Machine |

|

| For the auto-washing of up to 5 Colour Pipes per Load |

A reinforced Stainless Steel fabricated Wash Enclosure complete with Recycled Water Tank Base, having been suitably prepared to retain the following:

| • |

A Stainless Steel fabricated ~Trolley~ for supporting up to 5 Colour Pipes/Squeegees, inclusive of Locking Devices and Pipe connection arrangements to safely retain the Colour Pipes during the Wash Sequence. |

|

|

|

| • |

A suitably prepared Traveling Carriage mechanism, retaining 4 Spray Tubes fitted with Fan type Water Jets, being fed from a High Pressure Water Pump, system, inclusive of a pair of Nylon Brushes, each driven from Motor-geared units for the effective external cleaning of the Colour Pipes. |

| • |

Traveling Carriage, running on a purposely designed Guide Track arrangement, supported within the Wash Enclosure, and Driven via a ‘Rack and Pinion’ system from a Variable Speed Motor-geared Drive unit. |

| • |

Internal Cleaning of the Colour Pipes carried out by an independent Water Pumping System effecting a Re-circulated Water ~Flushing Cycle~, followed by a Clean Water ~Wash Cycle |

| • |

Electrical Control Cabinet, housing all the necessary Controls and related Electrical Switch-gear, ready prepared for Mains Incoming supply. |

|

| |

| |

| |

| |

| |

| |

|