|

|

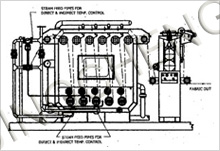

| Screen Printing & Dyeing Equipment |

|

|

WASHING RANGE HYDRA WASH TANKS, suitable for Woven Fabrics |

|

Each Wash Tank, - 15 Mts. Capacity, formatted as a reinforced enclosure 188 cm. High x 168 cm. Wide x (R./W. + 22 cm) Long, retaining a 3 in. BSP Water Drain, a 3 in. BSP Overflow/Counter-flow Pipe arrangement, and having been suitably fabricated to support the following:

|

| • |

A pair of Viewing/Access Doors, retaining sealed Tempered Glass-ware. |

| • |

Upper section Rollers comprising of a series of 6 inch Diameter Rollers running in Self-aligning Ball-Bearings, retained within Stainless Steel Sealed Bearing-housings. |

|

|

|

|

|

|

| • |

Lower section Rollers comprising of a series of 6 inch Diameter Rollers running in purposely designed Composite Carbon Bearings, retained within stainless steel Bearing-housings. |

| • |

Middle section Rollers comprising of a series of 5 inch Diameter Rollers running in purposely designed Composite Carbon Bearings, retained within stainless steel Bearing-housings. |

| • |

A Auto/Manual ~Direct~ Steam Heating, and ~Indirect~ Steam “Closed Coil” Heating arrangement, complete with the related Steam Valves to control required Working Temperatures (up to 90o Cent.). |

| • |

A Pressurized re-circulated Water Spray arrangement consisting of a Series of purposely Designed Spray Pipes to form a Water Blade type Jet Spray |

| • |

A High Pressure Pump complete with necessary Ball Valves to control each Spray Pipe, including a Water Filtering system with Quick-release interchangeable Filter elements. |

|

| |

|

SQUEEZE MANGLES (Nips) : 2 Bowl Transporter/Squeeze Mangles (Nips), Each Squeeze Mangle (Nip) comprising of a pair of heavy duty rigidly stayed fabricated Steel uprights having been formatted to support the following:- |

|

| • |

2 Pneumatically operated Heavy Duty ~Direct Acting~ Pneumatic Cylinders, complete with related pneumatic controls. |

| • |

Pressure Bowl, covered with ~80 Shaw~ Nitrile Rubber, with the journals retained in self-aligning Bearings mounted in Slide Housings, prepared for Clevis Pinion connection to the Pneumatic Cylinders. |

| • |

Drive Bowl, clad in Stainless Steel, running in Self-Aligning Bearings mounted in Fixed Housings, having one journal extended for connection to Squeeze Mangle Drive Arrangement. |

| • |

A 100 mm. Diameter adjustable Bowed Expander Bar, together with a Drip Tray connecting Squeeze Mangle to Wash Tank. |

|

| |

|