|

|

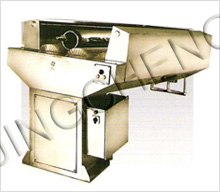

Screen Printing & Dyeing Equipment |

|

|

Rotary Screen Washing Machines |

|

TYPE I) SINGLE : For Auto-washing of One Rotary Screen up to 110 cm. Repeat.

TYPE II) DOUBLE : For Auto-washing simultaneously of Two Rotary Screens up to 72 cm.

Repeat, or One Rotary Screen up to 110 cm. Repeat.

THE ROTARY SCREEN WASHERS, are self contained units of robust Stainless steel construction.

Once the Screen/s is/are placed onto the Machines, the washing cycle is completely automatic.

|

|

|

| |

| The Nylon bristled Brushes support and rotate the Screen/s whilst being internally and externally sprayed by special high pressure Fan type Water Jets. |

|

| • |

A Screen thrusting arrangement connected to the Base section of the Wash Tank enacts a reciprocating scrubbing action of the Soft Nylon Brushes onto the Screen/s. |

| • |

A "Soft Start" Brush Drive system ensures delicate handling of the Screen/s motion. |

| • |

A Water Spray system comprising of 4 Spray Tubes retaining special Fan type Water Jets, complete with a high pressure Water Pump, all pre-piped ready for Mains connection. |

| • |

The Water Spray system includes an Electric Solenoid Valve arrangement, for isolating Sprays when washing individual Screens. |

| • |

The Wash Tank, being supported on a stainless steel cabinet, retaining a Motor-geared unit for the Brush Drive, complete with necessary chain wheels and chain tensioning arrangement. |

| • |

Electrical control panel housing process timers, and all other related Electrical switch-gear, all pre-wired, ready for incoming supply. |

|

| |

| |

|